GSEM compact magnetron SEM sputter coaters

GSEM compact magnetron SEM sputter coaters

Compact, automatic and easy to use efficient sputter coaters

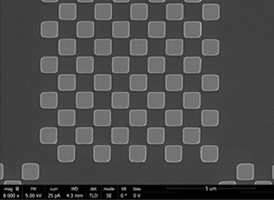

The GSEM G-series SEM sputter coaters represent a new generation of very efficient and really easy to use compact coating systems without the need for Argon process gas. The systems use either a Gold or a Platinum target. The SEM sputter coater creates a plasma to coat non-conductive or low conductive sample with gold or platinum to make the surface conductive which enable bright imaging and EDS analysis in the SEM. The coaters are cost-effective with quick cycle times and easy to change 50mm disc type targets. The available GSEM coaters are:

- GSEM G10 easy to use fully automatic, fast and efficient sputter coater, single button operation

- GSEM G20 versatile fully automatic sputter coater with full parameter control

GSEM G20 versatile fully automatic sputter coater with full parameter control

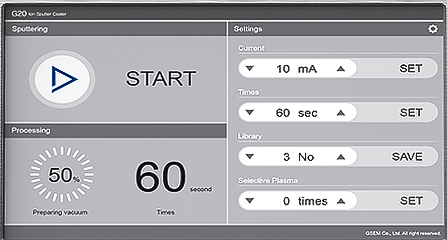

The GSEM G20 is a versatile SEM sputter coater which offers coating thickness control, easy operation and a coating library function through a 7”touch screen. Due to it compacts size, smaller target size and no use of Argon gas, this versatile coater has low operational costs. Control parameters are time, sputter current and selective plasma interrupt (stops coating during 10 seconds intervals) to avoid specimen heating. With control over these coating parameters, the user has full control over the desired coating thickness. The library function allows to store the coating parameters for 10 different procedures; it is truly a versatile automatic coater. The height adjustable sample stage has space for 7 standard Ø12.7mm pin stubs or 7 JEOL Ø12.5mm stubs or 7 Hitachi Ø15mm stubs or for larger samples such as metallographic embeddings. The versatile G20 SEM sputter coater utilizes an efficient planar DC magnetron sputter head with a low voltage plasma discharge, resulting in a cool sputter process. The G20 SEM sputter coater has been designed for standard SEM/EDS applications and for labs with a variety of different samples.

Main features of the GSEM G20 coater are:- Easy operation through 7” touch screen

- Auto coating cycle with One touch operation

- Coating parameter saving with Library function (up to 10 procedures)

- Full control over coating current and coating time parameters

- Low current and selective plasma option to prevent sample damage

- Adjustable sample table height

- Space for 7 standard SEM stubs or large metallographic sample

- Low operation costs – no argon and only 50mm diameter target size

- Small footprint

Specifications of the GSEM G20 versatile automatic SEM sputter coater:

| Target size / type | Ø50 mm / disc |

Target material |

Gold or Platinum (Au Ø50 x 0.1 mm standard) |

Sample table |

Ø50 mm for 7 pin standard stubs, 30mm height adjustment |

Chamber size (D x H) |

Ø140 x 100 mm |

Sputter Time |

1 to 600 seconds (1 sec/step) |

Ion sputter current |

1 to 10 mA (1mA/step) |

Vacuum / process gas |

0.26 mbar / residual air |

Operation |

7” Touchscreen |

Library function |

Stores parameters for up to 10 coating procedures |

Selective plasma function |

0 to 10 (1sec/step) interrupts coating in a 10 seconds interval |

Vacuum pump connection |

KF16 |

Dimensions (WxDxH) / weight |

380 x 240 x 250mm / 10kg |

Vacuum pump |

Value VRI-4, dual stage, 4m3/hr |

Accessories |

Vacuum Hose, KF16 Hardware, cable, Au target, manual |

GSEM G10 easy to use fully automatic, fast and efficient sputter coater

The GSEM G10 cool sputter coater has been designed for table top SEMs or compact SEMs and for high throughput labs. With its small footprint and no need for Argon gas, the G10 coater takes little space in an SEM lab. Operation is simplified by fully automatic operation, the operator only has to choose from 3 coating times = coating thickness; it is truly a “no-hassle” coater. The fixed sample stage has space for 7 standard Ø12.7mm pin stubs, 7 JEOL Ø12.5mm stubs or 7 Hitachi Ø15mm stubs. The G10 SEM sputter coater use a planar magnetron design with a low voltage AC plasma discharge which results in a cool sputter coating method. Efficient plasma at low vacuum ensures homogenous coating without sample damage. Average target uses is estimated for around 500 coating cycles.

Main features of the GSEM G10 sputter coater are:

- Fully automatic operation with just one click of a button

- Easy operation – insert sample and press Start

- Very efficient coater – cycle time of only 3 minutes from Start system to finish coating

- Single coating parameter choice – 20, 40 or 60 seconds

- Space for 7 standard SEM stubs

- Low operation costs – no argon and only 50mm diameter target size

- Small footprint

Specifications of the GSEM G10 fast and simple SEM sputter coater:

| Target size / type | Ø50 mm / disc |

Target material |

Gold or Platinum (Au Ø50 x 0.1 mm standard) |

Sample table |

Ø50 mm, fixed with removable disc for 7 pin stubs |

Chamber size (D x H) |

Ø140 x 70 mm |

Sputter Time |

20, 40 or 60 seconds |

Ion sputter current |

Fixed at 38 mA |

Vacuum / process gas |

Low vacuum / residual air |

Operation control |

4 push buttons (Start + 3 x time) |

Vacuum pump connection |

Ø16 mm hose connection |

Dimensions (WxDxH) / weight |

380 x 240 x 235mm / 10kg |

Vacuum pump |

Value VRI-2, dual stage, 2m3/hr |

Accessories |

Vacuum Hose, KF16 Hardware, cable, Au target, manual |

Ordering information for the G10 and G20 compact SEM sputter coaters, complete systems

|

|

|

|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||